Double the efficiency with game-changing picking solutions.

Excellent ROI for 100+ companies across 20+ countries.

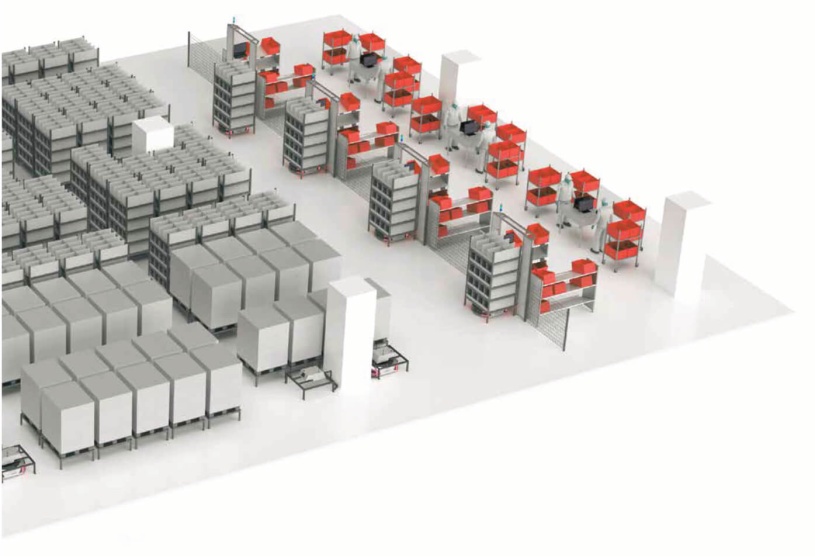

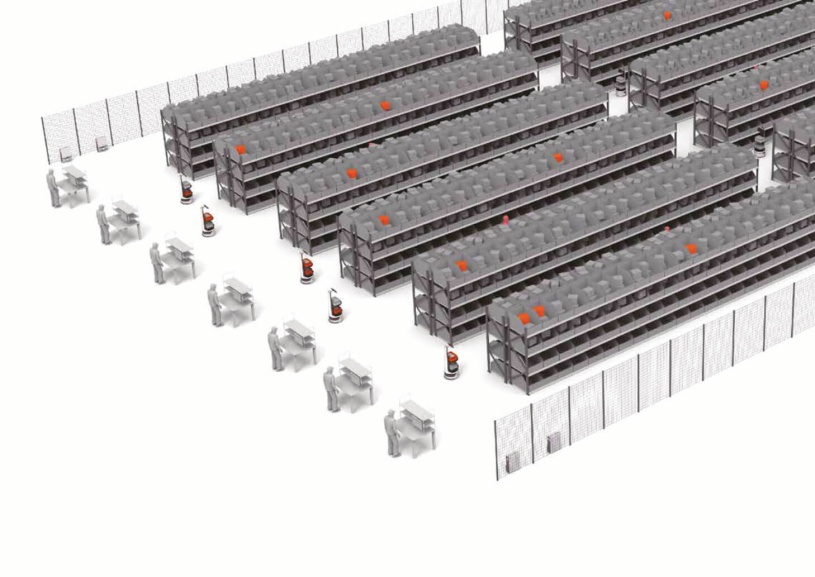

Goods-to-Person uses picking robots to improve accuracy by moving the inventory shelves and

pallets to the picking station. Picking efficiency is improved by two-to-three times. Geek+ offers

both single- and multi-layer goods-to-person picking solutions.

Goods-to-person picking utilizes AI to optimize picking efficiency and increase storage

capacity with the least amount of robots possible, ensuring rapid ROI.

One-stop goods-to-person solution with high storage, high throughput and high compatibility

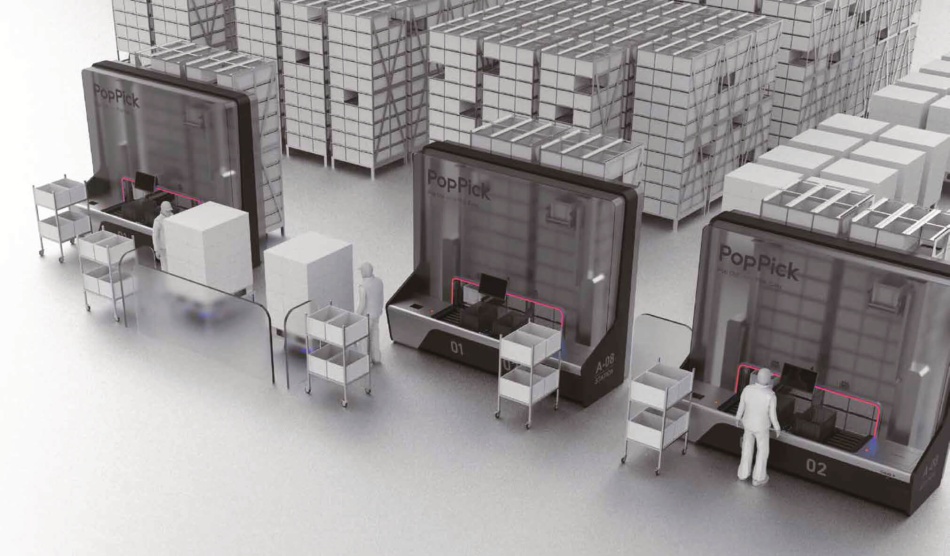

PopPick is our next generation, goods-to-person

picking solution for warehouse operations and

supply chain management. In a warehouse setting,

Geek+ picking robots carry movable racks

from storage locations to PopPick workstations

,The target totes(which are already stored on the

movable racks) are picked automatically by the

station and presented to the operator for easy picking. Compatible with items of varying sizes,

PopPick’s dynamic slotting support automatic

unmanned operations based on order forecasts

analyzed during idle time, hit rate improved to 10

totes.

Improve the Efficiency, Flexibility and Storage Capacity of your Warehouse.

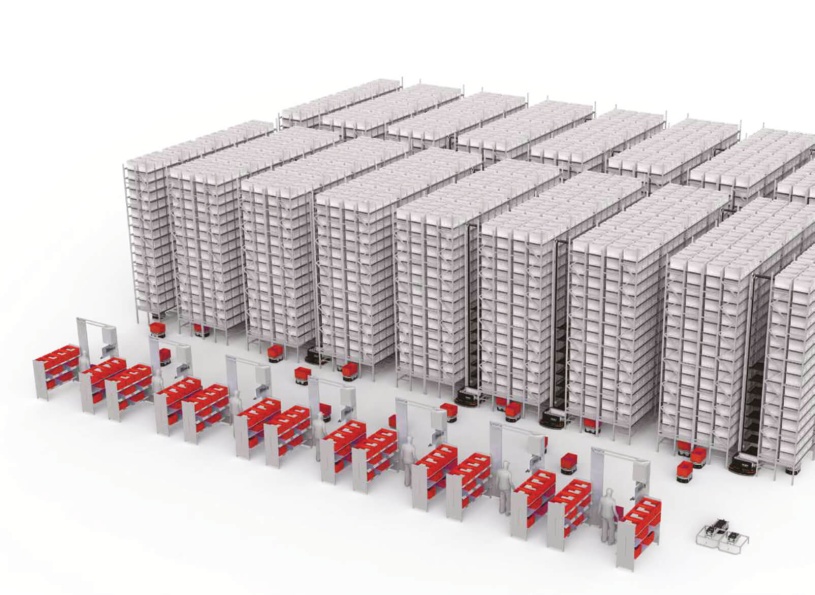

RoboShuttle is the Geek+ award-winning, tote-to-Person system featuring high picking efficiency, high-density double-deep storage capabilities, and narrow aisle design. Make full use of vertical warehouse space and maximize storage capacity with RoboShuttle robots‘ multiple tote-picking function and modular design.

RoboShuttle offers superior flexibility, efficiency, and ROI

The next-generation high-density tote-to-person

solution with high storage, efficiency, flexibility,

and cost-efficiency.

This solution pairs 5-8 meters high mobile robots that

stores totes of various sizes with a small picking robot that carries totes to the workstations.

Intensive storage and retrieval solution with high throughput

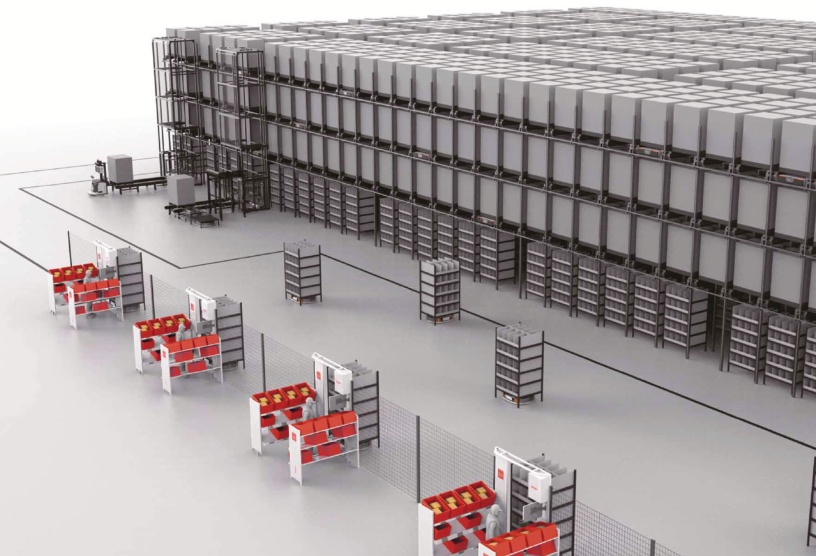

The 4-way shuttle solution is a new generation

of storage and retrieval based on the X

series 4-way shuttle robots to maximize the

use of the logistics center space. At the same

time, cooperate with P series picking robots,

integrated business and scheduling systems

to maximize throughput. It is a cost-effective

solution for high-density storage and high-frequency picking.

The multi-model integrated intelligent scheduling system enhances the cooperation between devices

and builds a safe, efficient and stable access system.

A storage and retrieval solution with high storage,

high efficiency, high flexibility

Combines a four-way shuttle system with a goods-to-person system to maximize space utilization and picking efficiency. Based on the strong picking capability of the goods-to-person system, relying on the four-way

shuttle stereoscopic racks to maximize the use of 3D space.

Highly flexible automated picking solution,

fast deployment, and rapidly effective

AislePick can significantly shorten the walking distance and improve the picking efficiency by 1.5~2x. A-series robots adopt laser and visual SLAM navigation, flexible to adapt to the complex environment of human-machine mixed traffic enhance safety and efficiency.